The Parmigiano Reggiano cheese making

"Only our milk "

We need about 600 liters of milk to make a 40 kg weight Parmigiano Reggiano wheel.

Here in the Agricola Giansanti we believe there are 3 fundamental points to make our cheese:

the milk, the dairy processing, the cheese aging.

We need about 600 liters of milk to make a 40 kg weight Parmigiano Reggiano wheel.

Here in the Agricola Giansanti we believe there are 3 fundamental points to make our cheese:

the milk, the dairy processing, the cheese aging.

The milk On cold winter nights, just small lights break the darkness of Parma's countryside. Under the

lit eaves, cows are in the line, diligently waiting to be milked, every evening, as a ritual that is

going on for generations.

The Agricola Giansanti's cattle breeding is uniquely made of holstein and Italian brown cows.

Every day they are fed on our farm fields' forage by the barn men. The continuous quality

inspections are led to guarantee an healthy milk, 100% made in Italy.

On cold winter nights, just small lights break the darkness of Parma's countryside. Under the

lit eaves, cows are in the line, diligently waiting to be milked, every evening, as a ritual that is

going on for generations.

The Agricola Giansanti's cattle breeding is uniquely made of holstein and Italian brown cows.

Every day they are fed on our farm fields' forage by the barn men. The continuous quality

inspections are led to guarantee an healthy milk, 100% made in Italy.

We need about 600 liters of milk to make a 40 kg weight Parmigiano Reggiano wheel.

Here in the Agricola Giansanti we believe there are 3 fundamental points to make our cheese:

the milk, the dairy processing, the cheese aging.

We need about 600 liters of milk to make a 40 kg weight Parmigiano Reggiano wheel.

Here in the Agricola Giansanti we believe there are 3 fundamental points to make our cheese:

the milk, the dairy processing, the cheese aging.The milk

On cold winter nights, just small lights break the darkness of Parma's countryside. Under the

lit eaves, cows are in the line, diligently waiting to be milked, every evening, as a ritual that is

going on for generations.

The Agricola Giansanti's cattle breeding is uniquely made of holstein and Italian brown cows.

Every day they are fed on our farm fields' forage by the barn men. The continuous quality

inspections are led to guarantee an healthy milk, 100% made in Italy.

On cold winter nights, just small lights break the darkness of Parma's countryside. Under the

lit eaves, cows are in the line, diligently waiting to be milked, every evening, as a ritual that is

going on for generations.

The Agricola Giansanti's cattle breeding is uniquely made of holstein and Italian brown cows.

Every day they are fed on our farm fields' forage by the barn men. The continuous quality

inspections are led to guarantee an healthy milk, 100% made in Italy.

The dairy processing

In the morning at the cheese factory, the milk left to rest from the previous night, so skimmed

in a all natural way, is poured into the copper cauldrons mixed with the fresh one, just arrived

from the early morning milking .

Inside the typical overturned bell-shaped cauldrons, the milk tends to clot. With a skimmer ,

an ancient tool of wood and iron , Our master cheese-maker carries out long and wise

movements by the “spino” an ancient wood and iron tool. It gives the curd a grainy texture.

Still in cauldrons, these minuscule granules are kept cooking for 50 minutes at 55 °C degrees.

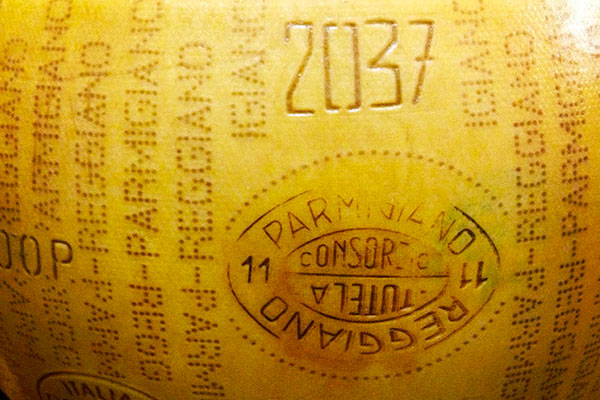

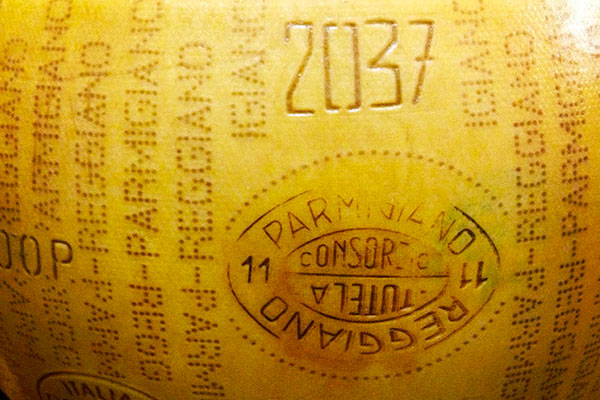

We have so formed a single mass of cheese, the cheese-maker cuts it into two parts. Wrapped

in cloth, they are placed in moulds, the moulds that give the Parmigiano Reggiano the typical

cylindrical shape. In it you can see month and year of manufacturing, the dairy-company serial

number ( 2037 ) and the unmistakable pitting over the circumference .

Each cheese is further more identified by a caseine plate that contains the progressive serial

number.

Every cheese is put for more than 20 days in large tanks filled with water and sea salt.

The cheese aging

After salting, about a month after being released, we bring cheese to the room of maturation.

Here each cheese is set over long wood rows, one row above the other. They form massive

walls of Parmigiano Reggiano, with ranging colours, from pure white fresh cheese to subtle

straw yellow more mature one.

In this temperature and humidity controlled place, cheese is allowed to rest under accurate

eyes of the master-cheesemaker; the outer part of Parmigiano cheese dry naturally, forming a

crust that is totally edible .

After 12 months, the Parmigiano Reggiano Consortium's experts examine each individual, by

tapping and typing and if they think it is aprropriate, they put the fire-brand mark on it. The

PDO (Protected Designation of Origin) Parmigiano Reggiano mark.

Each cheese is so selected and certified .

The longer the aging, the greater the friability of cheese and deeper the aroma. From a

minimum of 12 months it can therefore be aging for over 3 years .